Dairy Plant Design & Construction

)

Market trends and consumer demand often dictate what manufacturers produce and how they produce it.

We are revolutionizing dairy processing with expert solutions for superior quality and innovation

Stellar is a committed participant in the dairy processing industry, focusing on ensuring the quality and safety of fresh products. Acknowledging the critical nature of preventing contamination, Stellar provides mechanical, electrical, and infrastructure solutions from design to operation to ensure optimal efficiency, quality, and safety for its dairy clients throughout the entire project lifecycle.

From planning to execution, we can guide clients in engineering top-notch dairy processing and distribution facilities.

Stellar's dairy processing experts have revolutionized the industry with their state-of-the-art facilities, cutting-edge technology, and equipment, ensuring efficient and high-quality production. With many years of experience in the dairy industry, Stellar understands the challenges and demands of running a successful facility and can provide expert guidance and solutions for processing needs. Stellar takes a personalized approach to understanding the unique goals and requirements of each client, closely working with them to create customized solutions that meet specific needs.

Our clients say

With the assistance of Stellar and local contractors, we were able to construct this facility during the trying times of the pandemic with minimal interruption due to the diligence of all parties. This facility is now operating at full capacity and has the latest technologies that will allow fairlife to continue producing high-quality products to serve the needs of our consumers. Stellar's commitment to the success of this project was evident in their collaboration with the entire project team, their proactive approach to challenges, and the overall quality of their work."

We have the experience creating facilities for all types of dairy products

The dairy industry is continuously evolving, with probiotic drinks, drinkable yogurt, and kefir gaining popularity in the United States market. Millennial consumers also drive the demand for unique, gourmet flavors, showing more interest in rich, flavorful products made with wholesome ingredients than low-fat alternatives. Stellar has extensive experience working with clients to process farm-gate milk into a range of products, including popular items like packaged fluid milk, cream products, yogurt, butter, ice cream, cheese, and milk powders.

Cheese Plant Design and Construction

Designing the layout of a cheese plant to optimize workflow and minimize cross-contamination risks is of upmost importance. The production of cheese from milk involves various processes and requires allocating separate areas for different stages of cheese production, including milk reception, pasteurization, curdling, draining, pressing, aging, packaging, and storage.

Milk Powder Plant Design and Construction

Milk powder plants convert liquid milk into powdered form through processes like evaporation and spray drying. Different types of milk powders, such as whole milk powder, skim milk powder and whey powder, can be produced in these facilities. The layout of the milk powder plant requires separate areas for different stages of milk powder production, including milk reception, pasteurization, evaporation, drying, powder handling, packaging, and storage.

Ice Cream and Frozen Dessert Plant Design and Construction

Facilities that focus on the production of ice cream, frozen yogurt, gelato, sorbet, and other frozen desserts include processes like mixing ingredients, pasteurization, homogenization, aging (for some products), freezing, and packaging. From process flow design and utilities planning to sanitation and food safety considerations, Stellar is the only partner you need.

Butter and Margarine Plant Design and Construction

Butter and margarine plants produce butter, margarine, spreads, and related products with processes that involve churning cream to separate butterfat from buttermilk, followed by washing, working, and packaging. We have the experience to design and construct a butter facility that meets production needs, ensures food safety, and complies with regulatory requirements.

Yogurt and Fermented Dairy Product Plant Design and Construction

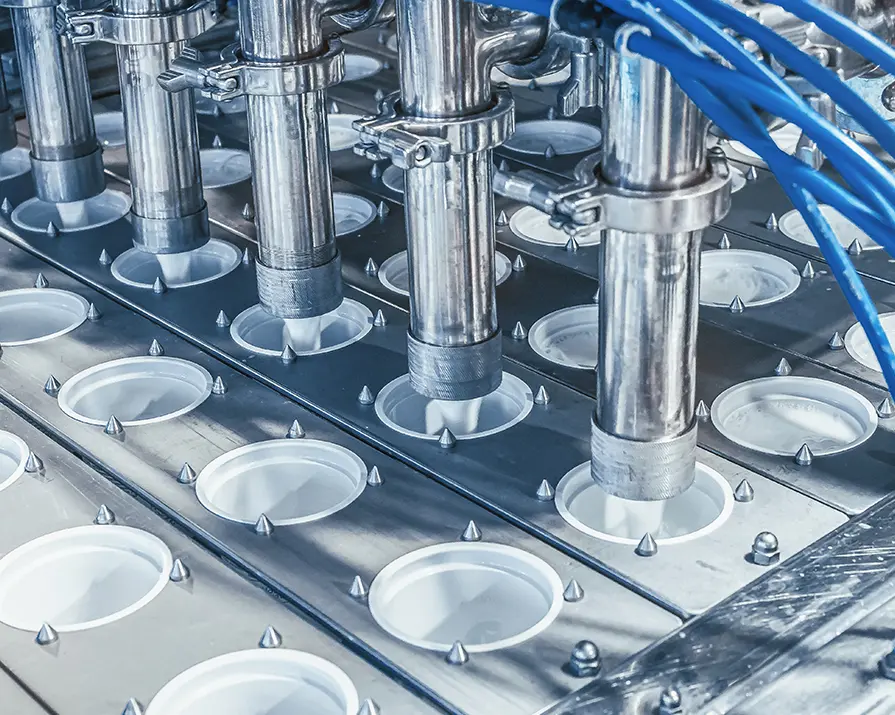

These facilities specialize in the production of yogurt, kefir, sour cream, and other fermented dairy products. Processes like pasteurization, homogenization, fermentation with specific bacterial cultures, flavoring, and packaging need to be considered when designing a layout to optimize workflow, minimize cross-contamination risks, and ensure efficient movement of personnel, materials, and equipment within the facility.

Cottage Cheese and Curd Plant Design and Construction

Cottage cheese and curd plants focus on producing fresh cheeses like cottage cheese, paneer, and ricotta. Processes involve milk pasteurization, acidification or enzymatic coagulation, curd cutting, cooking, draining, pressing, and packaging. Common equipment includes milk tanks, pasteurizers, cheese vats, curd knives, cooking equipment, draining tables, pressing equipment, packaging machinery, and utilities equipment.

Flavored Milk and Dairy Beverage Plant Design and Construction

Facilities specializing in flavored milk and dairy beverages produce products like chocolate milk, fruit-flavored milk, and milkshakes. Processes involve blending milk with flavorings, sweeteners, and additives, followed by pasteurization and packaging. Common equipment includes milk tanks, pasteurizers, flavor dosing systems, homogenizers, cooling tanks, packaging machinery, and utilities equipment.

Why Stellar?

Stellar is an authorized Rockwell Automation Integrator. It excels in designing and implementing control systems compliant with 3-A Standards and incorporating the latest best practices. This positions Stellar to effectively support the dairy industry's evolving needs.

Stellar's commitment to advancing the dairy industry and supporting its vital role is reflected in its membership in the International Dairy Foods Association. Stellar offers a collaborative and comprehensive approach to enhancing the efficiency, safety, and success of dairy processing endeavors, consistently monitoring innovation and market trends.

Our Clients Say

Nestlé has had an ongoing business relationship with Stellar for approximately 10 years, and they have successfully completed several major industrial design-build construction projects in various locations ranging from $1 million to $140 million in value. The projects were executed in a professional manner and were delivered within the established schedule and budget. Stellar’s professionals have the experience, knowledge and skill sets necessary to properly design and execute large projects effectively.”

The tools you need to improve your food or beverage plant’s efficiency. Discover how a facility assessment can benefit your business, which specific areas to examine to save you money, and what to look for in an assessment partner.

Stellar's leadership has the expertise and understanding necessary to advise you, even on the most complex challenges.