Stellar.net uses cookies to deliver the best possible experience to you. To continue using this website, you agree that we may store and access cookies on your device.

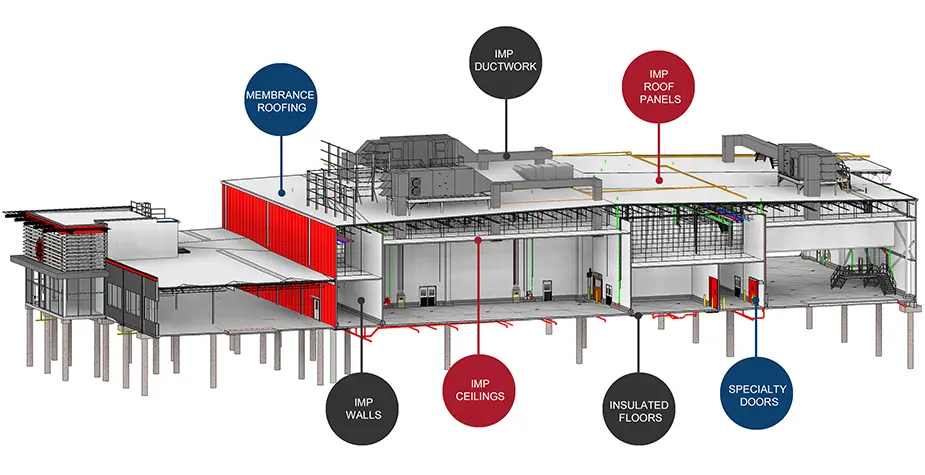

Thermal & Building Envelope Construction Services

)

Inside the design, construction and philosophy of this one-of-a-kind award-winning plant.

Comprehensive thermal and building envelope services for unmatched efficiency and stringent food safety standards

At Stellar Contracting, Inc. (SCI), we specialize in thermal and building envelope construction, focusing on maximizing energy efficiency and maintaining stringent food safety standards. We offer a range of services, including installation of insulated metal panels, roofing systems, underfloor insulation, and cold storage doors. Our dedicated team of experienced professionals enables us to provide innovative solutions tailored to each client's needs. We work alongside design and construction teams to conduct thorough reviews of the details of thermal construction.

Our design reviews identify the most effective materials and construction techniques that ensure energy efficiency and compliance with food safety standards. Our commitment to excellence has established us as the preferred provider of building envelope services.

Our Dedication to Quality, Safety, & Efficiency

At Stellar, we take great pride in our exceptional team of technicians, each trained to deliver high-quality installations while adhering to tight deadlines. Our personnel are equipped with advanced knowledge in the industry, covering all aspects of wall and roofing tasks. This allows us to maintain versatility within our teams, enabling effective adaptation to the varying demands of each project.

Our technicians undergo continual training, ensuring the knowledge framework is passed down from senior to junior members. This commitment to training raises the standard of work and strengthens the depth of our team's capabilities.

Vapor Barrier Integrity: Building Solutions for Low-Temperature Facilities

The focus on vapor barrier integrity is at the core of our services. Our installations are executed with great attention to detail, constructing vapor barriers with uncompromising integrity, which is essential for low-temperature environments that can reach temperatures as severe as -40 degrees Fahrenheit.

We specialize in the installation of insulated panel walls, roofing systems, doors, and ductwork to create an integrated structure capable of maintaining vital temperature controls and sanitary conditions. Our approach ensures your facility performs optimally, safeguarding the products stored or manufactured within.

Key considerations for low-temp door activation methods

When selecting the optimal activation methods for doors, several crucial factors must be considered to ensure efficiency, safety, and compliance with your specific needs. Here's a comprehensive guide to help you navigate these considerations:

- Budget Constraints

Evaluating the financial impact of various activation methods is essential. It's important to balance cost-effectiveness with functionality, ensuring you get the best value without compromising on quality. - Space Clearances

Assess the space around your doors to determine the most suitable activation method. Limited space might require compact or specialized solutions to maintain smooth operation without causing obstructions. - Heat and Humidity Conditions

Environmental factors such as heat and humidity can affect the performance of door activation systems. Opt for methods and materials resistant to these conditions to ensure long-lasting reliability and prevent malfunctions. - Frequency of Door Use

Consider how often the door will be used daily. High-traffic areas may benefit from automated systems designed to withstand frequent use, whereas manual or semi-automated solutions might adequately serve less busy doors. - Safety Requirements and Unique Operational Routines

Every facility has its own set of safety standards and operational routines. Ensure the activation method you choose aligns with these requirements, providing secure and efficient access while accommodating your operations' specific needs.

By carefully considering these elements, you can make a well-informed choice that improves both the functionality and safety of your door systems.

Preventative maintenance: Ensuring longevity of freezer floors

Preventative maintenance is vital for the longevity and reliability of freezer floors. At Stellar, we understand that frost heave is often an insidious threat to the integrity of freezer flooring systems. Regular maintenance of your underfloor heating system is fundamental for maximizing lifespan and preventing potentially devastating outcomes.

Neglected systems can lead to frost accumulation in subgrade soils, which may result in raised and cracked floors. These not only create safety hazards but can also disrupt operations and even lead to severe structural damage. Promptly addressing frost heave is crucial; the longer these issues are left unattended, the greater the risk of escalating damage.

Why Stellar?

Stellar delivers services that enhance operational efficiency while ensuring food safety. Our commitment to vapor barrier integrity and our use of high-quality insulated metal panels equip us to provide unmatched solutions for low-temperature and process buildings.

We pride ourselves on forging lasting partnerships with our clients, founded on trust and successful collaboration. At Stellar, we are not just service providers; we are your partners in excellence, ready to support you in achieving your operational and food safety goals.

Stellar's leadership has the expertise and understanding necessary to advise you, even on the most complex challenges.